You Are Here:Home > News Center

> Industry Dynamics

News navigation

Recommended news

- How to embody the barrier performance of PE plastic bottle

- How to demonstrate the barrier performance of PP cream jar

- Introduction of product uses by Jiangsu, Zhejiang and Shanghai PE bottle manufacturers

- Application of daily chemical plastic bottles produced by Jiangsu, Zhejiang and Shanghai manufacture

What are the characteristics of PCR regenerated material series

source:www.cssssy.com | Release time:2024-10-29

The PCR (Post Consumer Recycled) recycled material series has the following characteristics:

1、 Environmentally friendly and sustainable

1. Resource recycling and utilization: PCR recycled materials are made from plastics that are recycled after consumption. Through a series of processes such as collection, classification, cleaning, and processing of waste plastics, they are transformed back into usable raw materials for production. This process greatly reduces dependence on raw petroleum resources and lowers the environmental impact of plastic production. According to statistics, using PCR regenerated materials can reduce oil consumption and corresponding greenhouse gas emissions by about 70%.

2. Reduce landfill: If a large amount of waste plastic is not recycled, it will be buried or burned, which not only occupies land resources but also causes pollution to the environment. The use of PCR regenerated materials can effectively reduce the amount of landfill waste, extend the service life of landfills, and reduce air pollution caused by incineration.

3. In line with environmental trends: With the increasing global emphasis on environmental protection, more and more companies and consumers are paying attention to the environmental performance of their products. The products produced using PCR regenerated materials can meet the market's demand for environmentally friendly products, enhance the social image and competitiveness of enterprises.

2、 Performance characteristics

1. Diverse physical properties: The performance of PCR regenerated materials depends on the type of plastic being recycled and the processing technology. Generally speaking, PCR regenerated materials have physical properties similar to native plastics, such as strength, toughness, heat resistance, etc. After appropriate processing and modification, it can meet the performance requirements of different products. For example, in some plastic products that do not require high strength, PCR recycled materials can completely replace native plastics; In some fields with high performance requirements, such as automotive parts, electronic appliances, etc., the performance of PCR regenerated materials can be improved by blending with native plastics or adding modifiers.

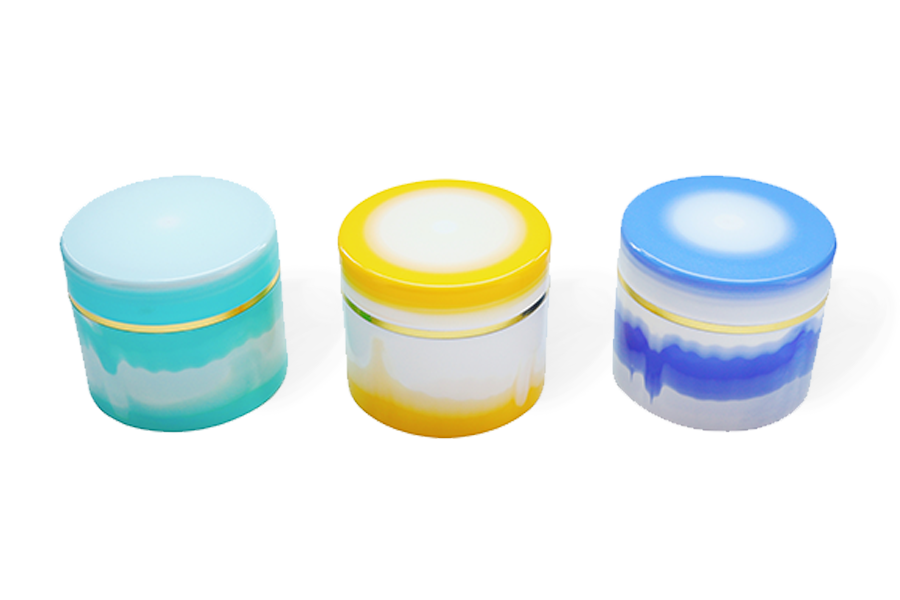

2. Color customization: PCR regenerated materials can be dyed by adding pigments or masterbatch to achieve different color effects. This allows manufacturers to customize product colors according to customer needs, meeting the diverse demands of the market. Meanwhile, the PCR regenerated material after staining has uniform color, good stability, and is not easily faded.

3. Cost advantage: As PCR regenerated materials are processed from recycled waste plastics, their cost is usually lower than that of virgin plastics. This gives products produced using PCR regenerated materials a certain cost advantage, which can improve the economic efficiency of enterprises. In addition, with the continuous advancement of recycling technology and the expansion of recycling scale, there is still room for further reduction in the cost of PCR regenerated materials.

3、 Widely applicable in various fields

1. Packaging industry: PCR recycled materials are widely used in the packaging industry, such as food packaging, cosmetics packaging, daily necessities packaging, etc. These packaging products usually have high requirements for material safety and hygiene, and PCR regenerated materials that have undergone strict processing and testing can meet these requirements. At the same time, the packaging industry is sensitive to costs, and the cost advantage of PCR recycled materials makes it highly competitive in the packaging field.

2. Construction industry: In the construction industry, PCR recycled materials can be used to produce plastic pipes, sheets, profiles, and other products. These products have the advantages of corrosion resistance, wear resistance, and light weight, which can replace traditional metal and wood materials, reduce construction costs, and improve the energy-saving performance of buildings.

3. Automotive industry: The automotive industry has high requirements for material performance, and PCR recycled materials can be modified and used to produce automotive interior parts, exterior parts, bumpers, and other products. These products not only meet the performance requirements of the automotive industry, but also have the characteristics of environmental sustainability, which is in line with the development trend of the automotive industry.

4. Electronic and electrical industry: In the electronic and electrical industry, PCR recycled materials can be used to produce products such as casings, plugs, sockets, etc. These products need to have good insulation performance, heat resistance, and mechanical strength, and PCR regenerated materials that have been properly processed can meet these requirements. At the same time, the electronic and electrical industry has increasingly high requirements for the environmental performance of products, and products produced using PCR regenerated materials can meet this demand.

1、 Environmentally friendly and sustainable

1. Resource recycling and utilization: PCR recycled materials are made from plastics that are recycled after consumption. Through a series of processes such as collection, classification, cleaning, and processing of waste plastics, they are transformed back into usable raw materials for production. This process greatly reduces dependence on raw petroleum resources and lowers the environmental impact of plastic production. According to statistics, using PCR regenerated materials can reduce oil consumption and corresponding greenhouse gas emissions by about 70%.

2. Reduce landfill: If a large amount of waste plastic is not recycled, it will be buried or burned, which not only occupies land resources but also causes pollution to the environment. The use of PCR regenerated materials can effectively reduce the amount of landfill waste, extend the service life of landfills, and reduce air pollution caused by incineration.

3. In line with environmental trends: With the increasing global emphasis on environmental protection, more and more companies and consumers are paying attention to the environmental performance of their products. The products produced using PCR regenerated materials can meet the market's demand for environmentally friendly products, enhance the social image and competitiveness of enterprises.

2、 Performance characteristics

1. Diverse physical properties: The performance of PCR regenerated materials depends on the type of plastic being recycled and the processing technology. Generally speaking, PCR regenerated materials have physical properties similar to native plastics, such as strength, toughness, heat resistance, etc. After appropriate processing and modification, it can meet the performance requirements of different products. For example, in some plastic products that do not require high strength, PCR recycled materials can completely replace native plastics; In some fields with high performance requirements, such as automotive parts, electronic appliances, etc., the performance of PCR regenerated materials can be improved by blending with native plastics or adding modifiers.

2. Color customization: PCR regenerated materials can be dyed by adding pigments or masterbatch to achieve different color effects. This allows manufacturers to customize product colors according to customer needs, meeting the diverse demands of the market. Meanwhile, the PCR regenerated material after staining has uniform color, good stability, and is not easily faded.

3. Cost advantage: As PCR regenerated materials are processed from recycled waste plastics, their cost is usually lower than that of virgin plastics. This gives products produced using PCR regenerated materials a certain cost advantage, which can improve the economic efficiency of enterprises. In addition, with the continuous advancement of recycling technology and the expansion of recycling scale, there is still room for further reduction in the cost of PCR regenerated materials.

3、 Widely applicable in various fields

1. Packaging industry: PCR recycled materials are widely used in the packaging industry, such as food packaging, cosmetics packaging, daily necessities packaging, etc. These packaging products usually have high requirements for material safety and hygiene, and PCR regenerated materials that have undergone strict processing and testing can meet these requirements. At the same time, the packaging industry is sensitive to costs, and the cost advantage of PCR recycled materials makes it highly competitive in the packaging field.

2. Construction industry: In the construction industry, PCR recycled materials can be used to produce plastic pipes, sheets, profiles, and other products. These products have the advantages of corrosion resistance, wear resistance, and light weight, which can replace traditional metal and wood materials, reduce construction costs, and improve the energy-saving performance of buildings.

3. Automotive industry: The automotive industry has high requirements for material performance, and PCR recycled materials can be modified and used to produce automotive interior parts, exterior parts, bumpers, and other products. These products not only meet the performance requirements of the automotive industry, but also have the characteristics of environmental sustainability, which is in line with the development trend of the automotive industry.

4. Electronic and electrical industry: In the electronic and electrical industry, PCR recycled materials can be used to produce products such as casings, plugs, sockets, etc. These products need to have good insulation performance, heat resistance, and mechanical strength, and PCR regenerated materials that have been properly processed can meet these requirements. At the same time, the electronic and electrical industry has increasingly high requirements for the environmental performance of products, and products produced using PCR regenerated materials can meet this demand.

Previous:

What are the advantages of PP Cream Tank Series

Next:

The six major development trends of plastic packa…

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone