You Are Here:Home > News Center

> Company Dynamics

News navigation

Recommended news

- How to embody the barrier performance of PE plastic bottle

- How to demonstrate the barrier performance of PP cream jar

- Introduction of product uses by Jiangsu, Zhejiang and Shanghai PE bottle manufacturers

- Application of daily chemical plastic bottles produced by Jiangsu, Zhejiang and Shanghai manufacture

Introduction of product uses by Jiangsu, Zhejiang and Shanghai PE bottle manufacturers

source:www.cssssy.com | Release time:2025-03-22

PE bottles are polyethylene plastic bottles, which can be divided into low-density polyethylene (LDPE) bottles, high-density polyethylene (HDPE) bottles and linear low-density polyethylene (LLDPE) bottles according to their density. They have a wide range of specific uses in many fields:

1. daily chemical industry

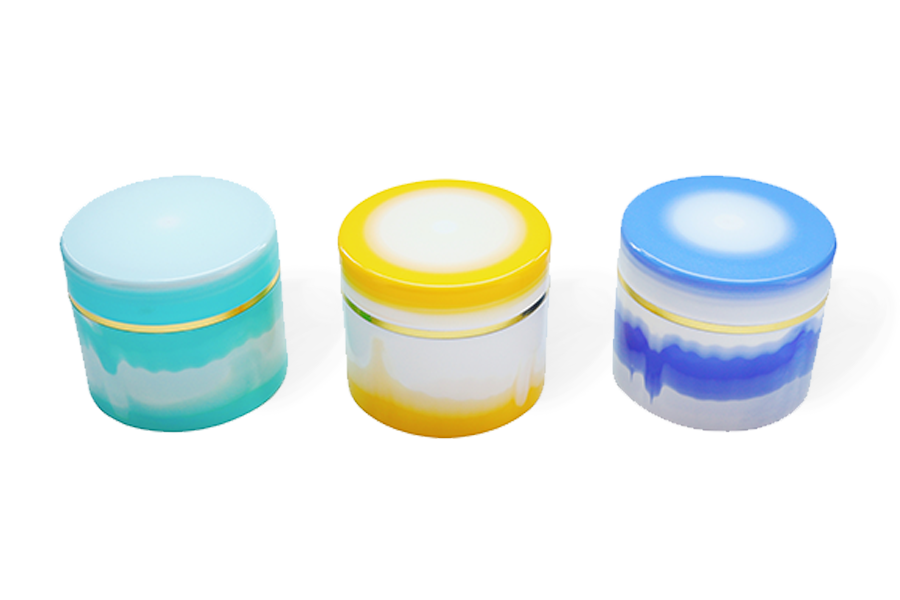

Package of skin care products: such as lotion, face cream, hand cream, etc., PE bottle can provide good sealing, prevent product leakage and deterioration, and its material is soft, which is convenient for consumers to squeeze and use products.

Packaging of cleaning products: HDPE bottles are often used for common detergent, detergent and softener. HDPE material has high strength and chemical corrosion resistance, which can withstand the weight and chemical properties of these cleaning products and ensure the safety of the products during storage and use.

2. pharmaceutical field

Drug packaging: used for packaging some oral drugs, such as granules, capsules, etc. PE bottles have good moisture resistance and barrier property, which can protect drugs from moisture and deterioration, and extend the shelf life of drugs. At the same time, its material meets the relevant standards of pharmaceutical packaging, with high safety.

Medical reagent packaging: some medical reagents, such as some test buffers and liquid reagents in reagent kits, will be packaged in PE bottles. The PE bottle can withstand the chemical properties of the reagent, and is easy to clean and disinfect, ensuring the purity and stability of the reagent.

3. food sector

Edible oil packaging: HDPE bottles are often used to package edible oil. They have good oil resistance and barrier properties, can prevent oxidation and rancidity of edible oil, and extend its shelf life. At the same time, PE bottles are light, not easy to break, and easy to transport and store.

Condiment packaging: such as soy sauce, vinegar, cooking wine and other condiments will also be packaged in PE bottles. The PE bottle can withstand the acidity and alkalinity of these condiments, and has good sealing performance, which can prevent the entry of odor and product leakage.

Beverage packaging: some small drinks, such as children's drinks and sports drinks, will be packaged in PE bottles. PE bottle has high transparency, can directly display the color of the beverage, and the material is safe, which meets the food hygiene standards.

4. industry

Chemical raw material packaging: used for packaging various chemical raw materials, such as paint, ink, glue, etc. PE bottles have good chemical corrosion resistance, can adapt to the characteristics of different chemical raw materials, and ensure the safety of raw materials during storage and transportation.

Lubricating oil packaging: HDPE bottle can be used to package lubricating oil, which has good oil resistance and can effectively prevent leakage and deterioration of lubricating oil. At the same time, PE bottles have good flexibility and are not easy to break due to collision, which is convenient for handling and use in industrial production.

1. daily chemical industry

Package of skin care products: such as lotion, face cream, hand cream, etc., PE bottle can provide good sealing, prevent product leakage and deterioration, and its material is soft, which is convenient for consumers to squeeze and use products.

Packaging of cleaning products: HDPE bottles are often used for common detergent, detergent and softener. HDPE material has high strength and chemical corrosion resistance, which can withstand the weight and chemical properties of these cleaning products and ensure the safety of the products during storage and use.

2. pharmaceutical field

Drug packaging: used for packaging some oral drugs, such as granules, capsules, etc. PE bottles have good moisture resistance and barrier property, which can protect drugs from moisture and deterioration, and extend the shelf life of drugs. At the same time, its material meets the relevant standards of pharmaceutical packaging, with high safety.

Medical reagent packaging: some medical reagents, such as some test buffers and liquid reagents in reagent kits, will be packaged in PE bottles. The PE bottle can withstand the chemical properties of the reagent, and is easy to clean and disinfect, ensuring the purity and stability of the reagent.

3. food sector

Edible oil packaging: HDPE bottles are often used to package edible oil. They have good oil resistance and barrier properties, can prevent oxidation and rancidity of edible oil, and extend its shelf life. At the same time, PE bottles are light, not easy to break, and easy to transport and store.

Condiment packaging: such as soy sauce, vinegar, cooking wine and other condiments will also be packaged in PE bottles. The PE bottle can withstand the acidity and alkalinity of these condiments, and has good sealing performance, which can prevent the entry of odor and product leakage.

Beverage packaging: some small drinks, such as children's drinks and sports drinks, will be packaged in PE bottles. PE bottle has high transparency, can directly display the color of the beverage, and the material is safe, which meets the food hygiene standards.

4. industry

Chemical raw material packaging: used for packaging various chemical raw materials, such as paint, ink, glue, etc. PE bottles have good chemical corrosion resistance, can adapt to the characteristics of different chemical raw materials, and ensure the safety of raw materials during storage and transportation.

Lubricating oil packaging: HDPE bottle can be used to package lubricating oil, which has good oil resistance and can effectively prevent leakage and deterioration of lubricating oil. At the same time, PE bottles have good flexibility and are not easy to break due to collision, which is convenient for handling and use in industrial production.

Previous:

How to demonstrate the barrier performance of PP …

Next:

Application of daily chemical plastic bottles pro…

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone