You Are Here:Home > News Center

> Industry Dynamics

News navigation

Recommended news

- How to embody the barrier performance of PE plastic bottle

- How to demonstrate the barrier performance of PP cream jar

- Introduction of product uses by Jiangsu, Zhejiang and Shanghai PE bottle manufacturers

- Application of daily chemical plastic bottles produced by Jiangsu, Zhejiang and Shanghai manufacture

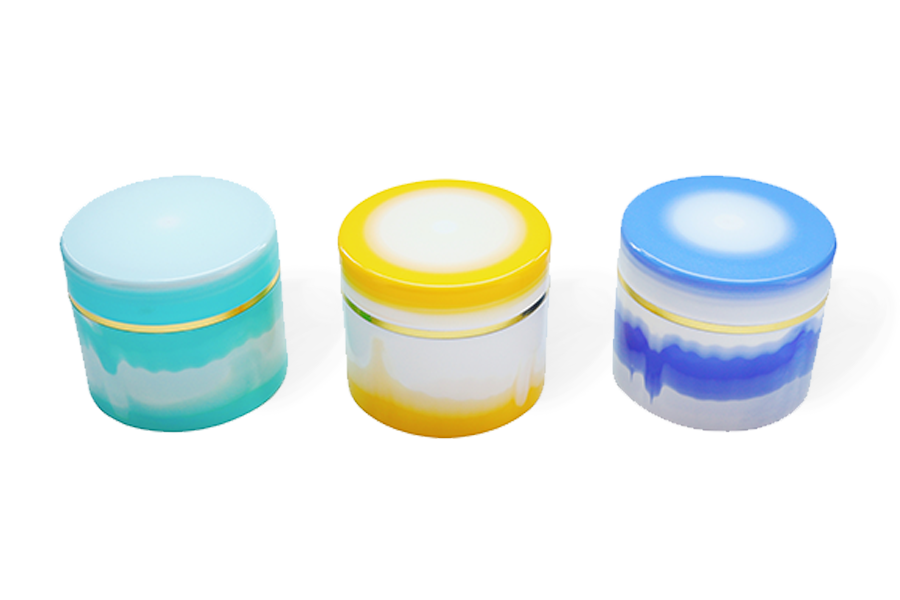

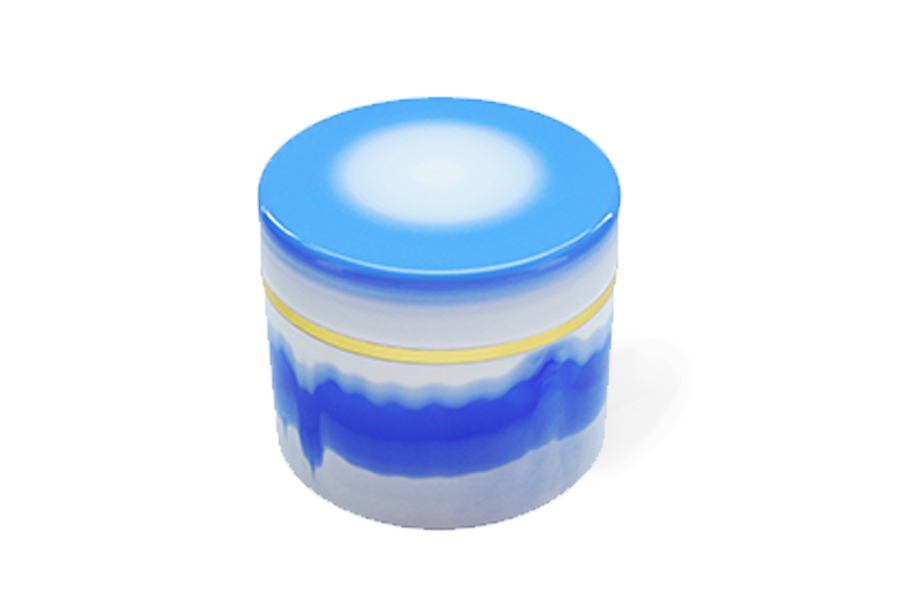

How to demonstrate the barrier performance of PP cream jar

source:www.cssssy.com | Release time:2025-03-24

The barrier performance of PP cream cans is mainly reflected in their ability to block substances such as oxygen, water vapor, and light, as follows:

1. Oxygen barrier

Stable molecular structure: PP has a tight molecular structure and high crystallinity, making it difficult for gas molecules to penetrate its molecular gaps. When oxygen molecules attempt to pass through the PP tank wall, they are hindered by molecular chains, thereby slowing down the rate of oxygen entering the tank.

Forming a barrier layer: Some PP cream cans use special production processes, such as adding barrier coatings to the can wall or co extruding multi-layer structures. The barrier layer can further enhance the barrier effect on oxygen, effectively reducing the contact between cosmetics and oxygen inside the can and preventing oxidation reactions.

2. Water resistance

Low water absorption: PP material itself has hydrophobicity, and water molecules are not easily attached and penetrated on its surface. When water vapor comes into contact with the PP cream jar, due to the weak affinity between PP molecules and water molecules, it is difficult for water vapor to enter the jar, thus maintaining the dryness of the cosmetics and avoiding deterioration caused by moisture.

Sealing design: PP cream cans are usually equipped with lids with good sealing performance, such as screw caps or flip covers. There are sealing gaskets or sealing structures between the lid and the can body, which can form a tight seal and prevent external water vapor from entering the can through gaps, further enhancing water resistance.

3. Light blocking property

Adding shading agents: In order to improve the light blocking performance of PP cream cans, shading agents or pigments such as titanium dioxide can be added during the production process. These sunshades can absorb or reflect ultraviolet and visible light, reduce the exposure of light to cosmetics, prevent photochemical reactions of photosensitive components in cosmetics, and protect the quality and efficacy of products.

Using colored cans: Some PP cream cans are made in dark or opaque colors, such as brown, black, etc., which can effectively block the passage of light and provide better light protection for cosmetics. For example, for cosmetics containing easily photodegradable ingredients such as vitamin C, using dark PP cream jars can extend their shelf life.

1. Oxygen barrier

Stable molecular structure: PP has a tight molecular structure and high crystallinity, making it difficult for gas molecules to penetrate its molecular gaps. When oxygen molecules attempt to pass through the PP tank wall, they are hindered by molecular chains, thereby slowing down the rate of oxygen entering the tank.

Forming a barrier layer: Some PP cream cans use special production processes, such as adding barrier coatings to the can wall or co extruding multi-layer structures. The barrier layer can further enhance the barrier effect on oxygen, effectively reducing the contact between cosmetics and oxygen inside the can and preventing oxidation reactions.

2. Water resistance

Low water absorption: PP material itself has hydrophobicity, and water molecules are not easily attached and penetrated on its surface. When water vapor comes into contact with the PP cream jar, due to the weak affinity between PP molecules and water molecules, it is difficult for water vapor to enter the jar, thus maintaining the dryness of the cosmetics and avoiding deterioration caused by moisture.

Sealing design: PP cream cans are usually equipped with lids with good sealing performance, such as screw caps or flip covers. There are sealing gaskets or sealing structures between the lid and the can body, which can form a tight seal and prevent external water vapor from entering the can through gaps, further enhancing water resistance.

3. Light blocking property

Adding shading agents: In order to improve the light blocking performance of PP cream cans, shading agents or pigments such as titanium dioxide can be added during the production process. These sunshades can absorb or reflect ultraviolet and visible light, reduce the exposure of light to cosmetics, prevent photochemical reactions of photosensitive components in cosmetics, and protect the quality and efficacy of products.

Using colored cans: Some PP cream cans are made in dark or opaque colors, such as brown, black, etc., which can effectively block the passage of light and provide better light protection for cosmetics. For example, for cosmetics containing easily photodegradable ingredients such as vitamin C, using dark PP cream jars can extend their shelf life.

Previous:

How to embody the barrier performance of PE plast…

Next:

Introduction of product uses by Jiangsu, Zhejiang…

【Related articles】

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone